More than a staple in a wardrobe, denim jeans have become a phenomenon worldwide and a classic product of style. Nevertheless, outside the shelves, there is an interesting history behind each pair. Pearl Global values transparency and excellence in manufacturing denim fabrics, providing excellence throughout the process, from the cotton fields to your favorite pair of jeans. Learning the denim-making process makes you bond with each article you use.

What Is Denim Fabric?

Denim is a sturdy cotton twill cloth, recognized for its diagonal weave and historical blue shade. Denim is traditionally made out of 100% cotton, but with new fabric technology, it could also be made out of elastane, polyester, or even recycled materials to allow stretch and performance. It is what casual wear is all about, and more so, the popular denim jeans, which are a hallmark product of denim cloth-making companies around the world.

A Brief History of Denim Fabric

Originating in 17th-century France as “serge de Nîmes,” denim gained massive popularity in 19th-century America. Denim jeans soon became essential workwear for miners and railroad workers. As denim cloth manufacturers refined the product, denim’s reputation soared—from blue-collar beginnings to high-fashion runways.

Denim Fabric Today: Global Importance

Denim manufacturers are of utmost importance in the textile economy in the USA, Europe, Asia, and Latin America. Denim has evolved from being simply a rough working apparel to a high-fashion and streetwear staple, and a source of long-term sustainability. As demand grows, denim manufacturing producers and suppliers are adopting green and socially responsible production methods to meet the needs of the present.

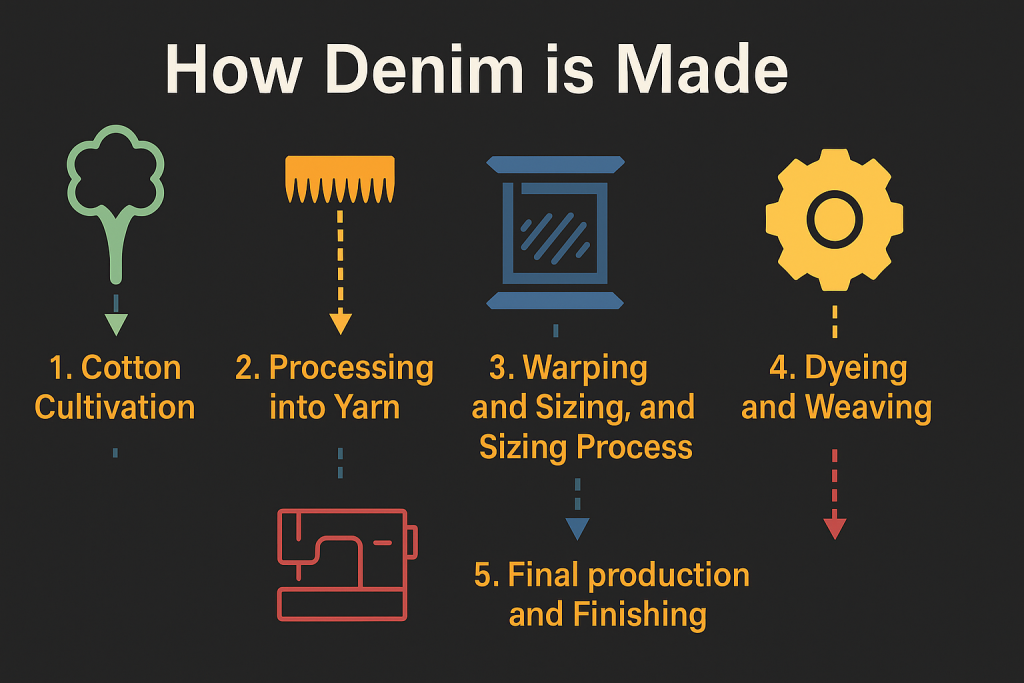

How Is Denim Fabric Made? Step-by-Step Process

Cotton Cultivation

The journey begins in the cotton fields. High-quality cotton, often organic or long-staple, is harvested and ginned to remove seeds. Many denim production leaders now prioritize sustainably grown cotton to reduce water and chemical use.

Processing into Yarn

After cleaning, cotton is spun into yarn. This involves carding (aligning fibers) and spinning (twisting them into threads). Yarn quality determines the strength and texture of the final denim fabric.

Warping, Beaming, and Sizing Process

Yarns are then arranged in parallel on large beams, a process called warping. Next comes sizing, where yarns are coated with a protective solution to reduce breakage during weaving. This is a key phase in the denim fabric manufacturing chain.

Dyeing and Weaving

This stage gives denim its signature look. The dyeing process, often indigo or sulfur-based, involves repeated dips and oxidations, known as rope or slasher dyeing. Then, yarns are woven in a twill pattern, creating that familiar diagonal texture. The interplay of dyed warp and white weft gives denim its classic blue-and-white contrast.

Final Production and Finishing

After weaving, denim manufacturers in the USA and globally finish the fabric through processes like sanforization (pre-shrinking), singeing (removing fuzz), and chemical or enzyme washes. The fabric is now ready to be cut, sewn, and styled into denim jeans.

Where Is Denim Fabric Produced?

Major production hubs include China, India, Pakistan, Turkey, the USA, and Bangladesh. The U.S. remains home to premium denim cloth manufacturers and mills specializing in heritage, organic, and performance fabrics. Meanwhile, Asia dominates mass production, with emerging interest in sustainable innovation.

Types of Denim Fabric

- Raw Denim: Untreated, stiff, and ideal for custom fading.

- Stretch Denim: Blended with elastane for flexibility.

- Selvedge Denim: Woven on traditional shuttle looms for a clean edge.

- Organic or Recycled Denim: Made with eco-friendly fibers and lower-impact dyes.

Top denim fabric suppliers now offer a range of textures, weights, and sustainable options to meet diverse consumer demands.

How Does Denim Fabric Impact the Environment?

Materials Used

Traditional denim relies heavily on water, synthetic dyes, and cotton grown with chemicals. Denim manufacturing can be resource-intensive if not managed responsibly.

Manufacturing Practices

Wastewater from the dyeing methods and finishing treatments can pollute local ecosystems. However, modern denim material suppliers are adopting water recycling, closed-loop dyeing, and energy-efficient processes.

Focus on Sustainability

Brands like Pearl Global are leading the way by sourcing from certified denim fabric suppliers, minimizing waste, and offering recycled cotton blends to reduce fashion’s footprint.

Certifications for Sustainable Denim

- Supima Certification: Ensures American-grown extra-long staple cotton, offering durability and softness with traceability.

- Cradle to Cradle: Assesses safety, circularity, and environmental performance, promoting regenerative denim production.

- Other eco-labels and what they mean: Look for GOTS, OEKO-TEX, or Bluesign, signs that your denim fabric meets high ethical and environmental standards.

Stages of Denim Manufacturing

The full denim manufacturing journey includes:

- Cotton sourcing

- Yarn spinning

- Warping and sizing

- Dyeing methods

- Weaving

- Finishing

- Garment design and sewing

Every stage influences the look, feel, and sustainability of the final product.

Challenges in Denim Manufacturing

- Water Use: Traditional dyeing consumes large volumes of water.

- Wastewater Treatment: Without treatment, dyeing discharge pollutes rivers.

- Fast Fashion Pressure: Rapid cycles strain ethical production timelines.

- Supplier Transparency: Tracing origins across supply chains is still a challenge for some denim fabric suppliers.

- Sustainable Washing: Denim washing during mass production can consume thousands of liters of water per pair unless optimized with efficient, low-impact techniques.

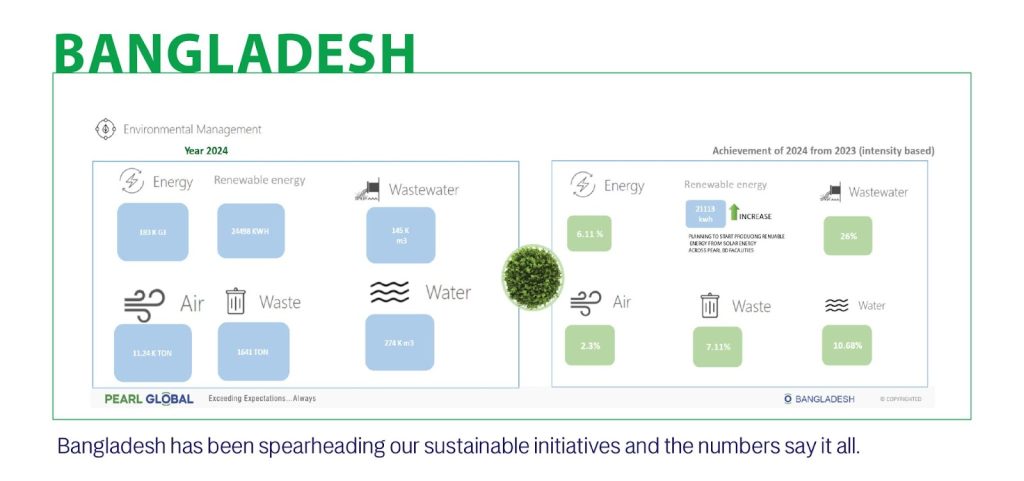

Sustainable Denim Washing at Scale: Pearl Global’s BD Facility

While denim fabric production often focuses on cotton sourcing, dyeing, and weaving, one of the most overlooked yet critical areas for sustainability is the denim washing process, especially during bulk manufacturing. Denim washing traditionally consumes vast amounts of water and chemicals to achieve different finishes and textures.

At Pearl Global, we have made substantial strides to counter this challenge through transformative investments at our Bangladesh facility, which has become a benchmark for sustainable washing in the denim industry.

In Phase 1, the facility implemented a 35 m³/h Ultra Filtration (UF) and 20 m³/h Reverse Osmosis (RO) system for advanced wastewater recycling. In Phase 2, the upgraded plant will handle up to 120 m³/h of wastewater, with RO output reaching 40 m³/h, enabling the reuse of treated water back into the denim washing process.

Complementing this, we’ve installed 297 KWp solar panels across key buildings, making the washing unit highly energy-efficient and reducing dependency on non-renewable energy sources.

These integrated systems allow us to conserve water, minimize environmental impact, and maintain high-performance standards, without compromising on the creative finishes that denim requires.

Pearl Global’s commitment to circular and responsible denim production is not just about compliance, it’s a strategic initiative to lead the future of sustainable fashion.

Bring Your Denim Vision to Life

Partner with Pearl Global for premium, sustainable denim manufacturing tailored to your brand’s needs.

Contact Us Today →Future Trends in Denim Fabric Production

Expect to see:

- Laser Finishing: Reduces water and chemicals.

- Eco Dyes & Bio Enzymes: Clean, plant-based dyeing solutions.

- Circular Fashion Models: More recycled denim programs.

- Digital Printing: Customized jeans with lower environmental cost.

Denim manufacturers in the USA and globally are embracing technology to redefine quality and sustainability.

Is Denim Sustainable?

It can be; if made consciously. Using organic cotton, ethical dyeing methods, low-impact processing, and certified materials transforms denim from a high-impact product to a responsible wardrobe staple. By choosing verified denim fabric suppliers and supporting denim cloth manufacturers with eco goals, brands can significantly reduce their environmental footprint.

Conclusion

From humble cotton fields to cutting-edge denim mills, denim fabric manufacturing is a complex, fascinating process. It involves traditional craftsmanship, innovative technology, and a growing commitment to sustainability. Whether you’re sourcing from denim manufacturers in USA or exploring global partners, understanding this journey helps you create more thoughtful, responsible fashion.

At Pearl Global, we’re proud to be part of this evolution, working with ethical denim material suppliers, embracing advanced production processes, and delivering stylish, sustainable denim jeans for conscious consumers worldwide.

FAQs

What is denim fabric made of?

Denim fabric is primarily made from cotton, often woven in a twill pattern for durability. Modern versions may include elastane or recycled fibers, making them more flexible and sustainable for various fashion applications.

What is the process of denim fabric manufacturing?

Denim fabric manufacturing involves cotton cultivation, yarn spinning, warping, dyeing, weaving, and finishing. Each step is essential in creating the final fabric used in jeans and other denim garments.

What is the best dyeing method for denim?

Indigo dyeing is the most common for denim, especially in rope or slasher dyeing techniques. Sustainable dyeing methods now include eco-friendly indigo and water-saving technologies to reduce environmental impact.

Who are the top denim manufacturers in the USA?

Leading denim manufacturers in the USA include Cone Denim and Mount Vernon Mills. These companies are known for high-quality, ethically produced denim with a focus on innovation and sustainability.

How do denim cloth manufacturers ensure quality?

Denim cloth manufacturers maintain quality through strict raw material sourcing, advanced machinery, skilled labor, and adherence to global certifications like OEKO-TEX or GOTS, especially in the finishing and dyeing process.

Is denim fabric sustainable today?

Yes, with the rise of organic cotton, recycled fibers, and low-impact production processes, denim is becoming more sustainable. Many denim fabric suppliers now offer eco-certified options to reduce the environmental footprint.